A long way to the first tangible R150

First copies of the new R150 should already be available at the end of 2016. It then took a little while until delivery really started in the third quarter of 2017. Since then, I have been looking for watch manufacturers who use this movement.

The first manufacturer I found was the American company Shinola, which used the R150 in the Lake Erie Monster Limited Edition. Unfortunately, at a price that did not speak in favor of buying the watch primarily because of the movement. Then I found a Kickstarter campaign of the Swiss fashion label EINSTOFFEN, in which the watch model Altenalptürm was offered with a Ronda R150. I ordered an Altenalptürm watch, and was disappointed when they sent me a watch with a Sellita SW-200 instead of a Ronda R150. So I sent it back. In the meantime I had already written to Ronda in Switzerland and their representative in Germany, Ermano, and asked if I could buy or inspect an R150 somewhere. Both did not feel like answering. Even the big watch furniture dealers Boley and Flume could only tell me that the Ronda R150 is not (yet) available.

Then, in late March 2018, a ray of hope: I stumbled over the Ukrainian watch manufacturer Kleynod. He announced on his website that he now equips all automatic watches with the Ronda R150. About two weeks later she was with me, the Kleynod K 348-510:

Technical data of the R150

- Diameter 11 1/2”’ (26.00 mm)

- Height 4.40 mm

- 3 Hands (sweeping second: hacking, minutes, hours)

- Date at 3H (quickset)

- Automatic, bidirectional winding, manual winding possible

- Swiss lever escapement

- 25 Jewels

- Frequency of balance 28’800 vibrations per hour

- Incabloc anti-shock system

- Lift angle of balance 51°

- Power reserve 40 h

- Regulation

- Avarage rate 12 s/d ±12 s/d in den Lagen CH, 6H

- Maximum variance in all positions 30 s/d

- Isochronism over 24 h ±20 s/d

A first look inside

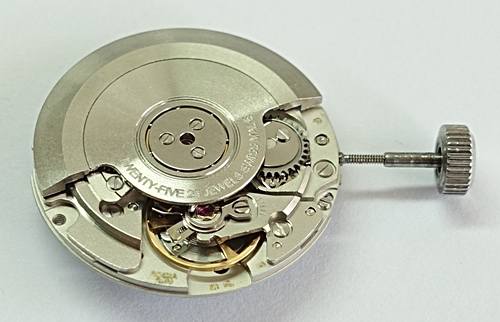

Let’s start with a first look at the open back of the watch:

There is a lot of space between the movement and the edge of the housing. Relatively small movements in large cases inevitably lead to the fact that the date is not near the edge of the dial, but relatively far inside. Here, however, the manufacturer of the watch has managed it quite well by optically positioning the date on a circle located further inside.

By pressing the setting lever push button, the crown including the winding stem can be removed. The movement can be taken out of the case to the rear:

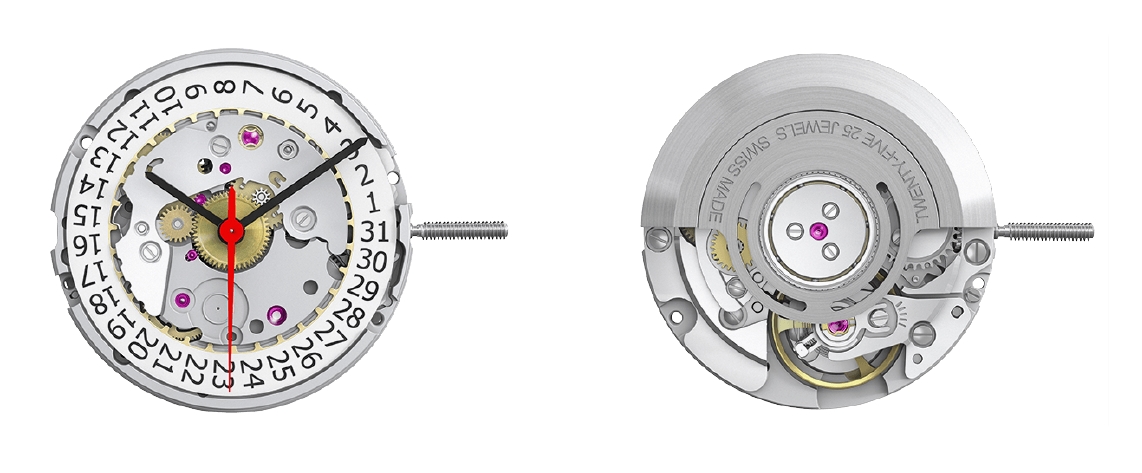

After removing the hands and the dial, we have the movement in front of us:

You can see immediately that there is no decoration on the movement, like perlage or geneva stripes. The engraving “TWENTY-FIVE 25 JEWELS …” on the rotor looks rather rough and the laser markings next to the balance are barely legible. Not a beauty, but pure technology instead.

The automatic unit

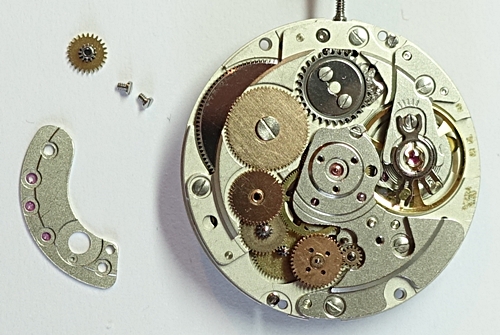

Now let’s start to dismantle the movement. The ball-bearing rotor is held by three small screws. Underneath you can see a rather small automatic bridge, which looks almost like a banana. As with many more modern movements, such as the Miyota 9015, the automatic unit is integrated into the main plate, and not an extra modul such as in the ETA 2824-2.

On the top side of the automatic bridge is a drive wheel (gold colored), which is directly driven by the gear rim of the rotor. It is only plugged in there and is held in place by the inner ring of the rotor. So be careful that this part does not suddenly disappear when the rotor is removed!

Under the automatic bridge it looks like this:

Five wheels for the automatic, that’s pretty much. To explain the automatic, I have plugged in the drive wheel A, which is actually located above the automatic bridge:

The Ronda R150 has a bidirectional winding automatic. Therefore, there must be a mechanism that causes the wheels to rotate in the same direction at a certain point in the automatic gear train, regardless of the direction in which the rotor actually rotates.

Here this mechanism consists of a pawl winding wheel KL and a reverser wheel W. The first reduction wheel R1 then always rotates in the same direction. The same applies analogously to the reduction wheels R2 and R3 lying behind R1. R3 can also be referred to as a winding-up wheel, since it ultimately winds up the spring in the barrel through the ratchet wheel S. The reduction wheels are needed to translate the rapid rotation of the rotor into a slow winding rotation of the ratchet wheel.

The crown wheel KR serves to wind the movement manually. Since the automatic rotates the ratchet wheel, the crown wheel would actually rotate as well. However, it can slide a little bit, so that it can avoid the reverse rotation and simply slip through.

So far, so good, but how exactly does it work with the pawl winding wheel and the reverser wheel?

The pawl winding wheel KL consists of two superimposed wheels and a pinion. Inside is a construction of small pawls, which ensures that the pinion only rotates jointly when at least one of the two wheels rotates to the right (seen from above).

So if we manage that the two different directions of rotation of the rotor via the drive wheel A cause one of the two wheels of the pawl winding wheel to rotate to the right, then the pinion will always rotate to the right regardless of the direction of rotation of the rotor. Accordingly, the reduction wheel R1 driven by this pinion will also always rotate in the same direction. Here, the reverser wheel W comes into play. It consists of two superimposed wheels that are rigidly connected (see picture above).

The following picture shows the interaction of these components:

The rotor rotates to the left, so the drive wheel A thus rotates to the right, because with each transition from one wheel/pinion to another, the direction of rotation changes. The pinion fixed to A also rotates to the right and simultaneously drives the upper wheel of the pawl winding wheel KL and the upper wheel of the reverser wheel W. Both wheels then rotate to the left. Now comes the trick: the lower wheel of the reverser wheel W, which is rigidly connected to the upper wheel of W, now drives the lower wheel of the pawl winding wheel KL, which thereby rotates to the right. So at KL the upper wheel rotates to the left, the lower wheel to the right. As mentioned above, it is sufficient that one of these two wheels rotates to the right so that the pinion of the pawl winding wheel KL also rotates to the right, no matter in which direction the other wheel of KL rotates!

Now it’s quickly explained w hat happens when the rotor rotates to the right instead of the left:

At the pawl winding wheel KL the upper wheel now rotates to the right, the lower to the left. As one of them rotates to the right again, the pinion of the pawl winding wheel also rotates to the right again and thus in the same direction as above.

Beneath the barrel bridge and the train wheel bridge

After the slightly complicated technique of the automatic, it is getting easier now. In the next picture, the balance, the barrel bridge (top left) and the train wheel bridge (bottom left) were removed. Unfortunately, on the R150 the train wheel bridge covers a bit of the barrel bridge, so that the barrel bridge cannot be removed without also removing the train wheel bridge. This is not really repair friendly.

On the barrel bridge you can see two specific features of this movement:

- There is a jewel bearing for the barrel (also on the dial side)

- The click engages with the crown wheel and not, as usual, with the ratched wheel

Under the bridges, a very classic structure comes to light, which holds no surprises:

The power transmission goes from the barrel F over the great wheel G, the third wheel K to the directly driven second wheel ZS, and from there to the escape wheel A.

SS indicates the stop-second hacking mechanism. When the crown is fully pulled, the small lever presses on the balance wheel (indicated by the blue circle), so the movement stops while the hands are being set.

Except for the pallet bridge and the pallet fork all parts are now taken away from the bridge side:

The dial side

Let’s continue with the dial side and remove the date indicator maintaining plate first.

Very nicely done: there are no small springs that say goodbye when the date indicator maintaining plate is lifted off.

The setting wheel (red circle in the next picture) is movably mounted and serves either to set the hands (crown pulled completely) or to turn the date corrector DK (middle position of the Crown) over a tiny intermediate wheel (green circle in the picture). The date corrector is used to manually adjust the date.

In normal operation, the date indicator driving wheel DM advances the date indicator disk every 24 hours by one day. The mechanism on the date indicator driving wheel ensures that the date changes abruptly at midnight, and not slowly.

Here all the components of the dial side are removed, except for the setting lever spring and the underlying parts:

Around the setting lever spring, it looks rather confusing at first:

If we remove the setting lever spring, it’s getting easier. Fortunately, there is no spring that could fly away. Instead, all spring elements have been integrated into the corresponding components.

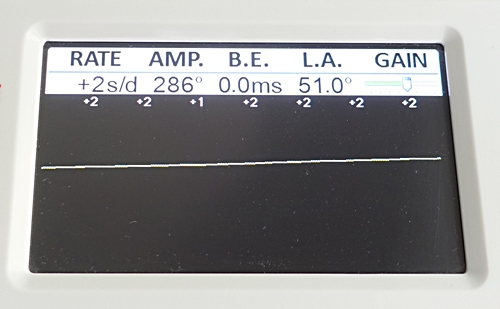

On the timing machine

So much for the theory, but how well does the movement work in practice? There is of course no long-term experience yet, since the movement is still very new.

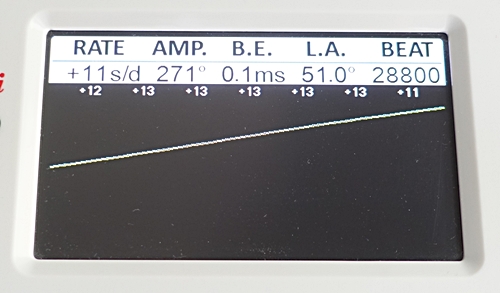

On the timing machine, the values are very stable in all positions, but they vary considerably depending on the position. In my tests, the maximum deviation between the positions was 20 seconds per day. This is within the specification of the manufacturer (maximum 30 s/d).

The average rate over all six positions is about +8.5 seconds per day. Not record-breaking, but fine.

The amplitude was between 290 ° in the horizontal positions (dial up and dial down) and about 270 ° in the hanging positions (crown left, right, up, down). And the beat error was between 0.0 and 0.1 ms in all positions. So there is nothing to moan about.

Conclusion

The R150 is certainly an important building block for Ronda to re-enter the market for mechanical watch movements. Technically, it offers solid home made work without special refinements. One or the other production step may need to be optimized a bit. For example, I found some oil splashes on and around the pallet fork, as well as a blob of oil around the setting lever push button.

A watch movement that could be well received by smaller watch manufacturers in particular, if they are looking for a Swiss Made movement. And if Ronda manages to produce large enough quantities of good quality at a good price. The movement is not fully compatible with the ETA 2824-2 due to the slightly different height (4.4 vs. 4.6 mm). Both movements have the same stem mounting height, therefore it is possible to create watch cases that fit both the Ronda R150 and the ETA 2824-2. Time will tell if Ronda will succeed with the R150.

I own a NOBE Swiss Made Automatic, company started in 2015, that has the Ronda R150, I’m very happy with the watch overall, Ronda may not be as popular as ETA, i see Ronda as good as any other watch mechanism manufacturer.

The US watch Co “Lume-tec” uses this movement in some of their watches FYI.

Well done explanations with photos to support them. Thank you.

Hi

Being an Aussie I have been wanting to support our Industry and now feel I can with the Adina product using this movement.

Thanks for the information

The Dansk Tuseno Co.Watches produce his Tuseno Diver using Ronda 150 for approx 1k.. Honestly I prefer Eta 2824 NOS or Selita 200

Tusenö is a Swedish manufacturer 🙂

An Australian company – Adina Watches – is using the Ronda R150 in their “Country Master Underground”. It’s a watch marketed at underground mine workers. The watch case is angular and 36mm at its smallest. My watch is very accurate and reliable.

Gday considering buying same watch

21/9/24 any updates on quality of your watch

Thanks. Peter

I didn’t wear this watch for a long time. Therefore I can’t give you an update.

According to their website Ronda has already phased out the production of the R150. So it was probably not a great economic success.

I have a KLOC Uhrwerk Deep Scuba 500 Automatic that uses the movement. It is on the market for about a year now. I’m very content with the watch.

Love your work. Excellent!

Any idea about material Balance wheel is made of and hairspring?

Thank,

Phoulis

No, that seems to be Ronda’s secret.

Hi Andreas love your website ..i have a question schaumburg watch co adsivsed me they will use the r150 movemnt as a manual wind adjusting for strict manual do you see any issues with the ratchet wheel being used to wind the watch often since it was built as an automatic movement ? can this movemnt handle that ? jsut curious thank you

Sorry, I don’t have enough experience with this movement to give you a qualified answer.

Andreas: I have followed the story about the Ronda R150 for several years, but, like you, never found a watch company that used it! I appreciate your detective work, searching the world for a watch with the R150. Perhaps Ronda found it difficult to interest Swiss mid and lower end watch companies to use their first mechanical movement in decades, preferring to use established and proven movements. Thank you for your in depth technical review of this movement.

Incidentally, I wrote numerous articles for International Watch (iW) magazine on the history of various mechanical movement companies. Two of them were titled “The Legend of Valjoux” (Nov. 2008) and “The Lemania Legacy” (July 2011). If you do not have copies of these articles, send me an email. Anthony Young, Manchester, Tennessee

ETA and Sellita documents tell you absolutely everything but the Ronda stuff is very vague. I built a watch using a 2824 and by it was finished and I added up what I had spent it was not particularly cheap, but unique. At the price quoted the Ronda is competitive with a Seagull “clone” and attractive for a project. I dont suppose you notice d how the dial compared with a 2824, feet position and date window.

Thanks for the quick reply

Hi, Just discovered this movement for the first time today. Similar in many ways to a 2824 but definitely not a copy. It looks interesting for a project, having seen it offered on a site for $80(if its genuine) What I have not been able to find is the information for the hands. Very comprehensive article.

Hi Phil,

you are right, Ronda does not give any information about the hands, at least not publicly available. I didn’t check, but I bet that the hands for the ETA 2824-2 will work fine.

I’d be interested to know what site was selling for that price? Keen to get hold of 1 or 2 for a project.

Great tear down and review of the movement Andreas.

If you only want to buy 1 or 2 of the, your price will likely be around 150 Euros for each! If you buy 1.000 pcs, it’s a different story…

Nice analysis of this promising new movement. Would be nice to see bigger pictures and side-by-side comparison with the ETA. The Ronda appears laid out in a very similar fashion.

Why is it not compatible, the width and stem height appear identical to the ETA 2824?

The 2824 is 0.2 mm higher than the Ronda R150. This means that 0.1 mm are missing on each side, even if the stem height is the same.

Stem height (1.8mm) is dial to stem distance so they’ll be in the same positions, the Ronda should just have an extra 0.2mm clearance between rotor and case back. I’m pretty confident they’ve sized it to win new watch and repair business away from ETA.