The Citizen watch shown here dates from 1971, so it is already 50 years old! The Citizen 6000 calibre automatic movement was built from 1966 onwards.

Before we start with the actual topic, first a few technical data of the movement:

- Indication of hours, minutes, sweeping second (non-hacking), date with quick-set mechanism

- Automatic, winding in both directions, manual winding possible

- Diameter 10 1/2´´´ (French lines) = 23.3 mm, Hight 5.0 mm

- 21.600 beats per hour (bph)

- Swiss lever escapement

- 17 jewels (there is also a version with 21 jewels)

- Glucydur balance

- Shock protection: Citizen Parashock 1

From the same movement family there is also a calibre 6500 with automatic, day and date as well as a calibre 6080 with manual winding and without day or date. In addition, there are the calibres 6001 and 6501, in which a few parts have been changed in comparison to the 6000 and 6500. In my opinion, however, not always for the better, since, for example, the date driving wheel made of metal was replaced by a plastic part.

Citizen movements are unfortunately not a feast for the eyes in most cases – but they are as reliable as a tractor.

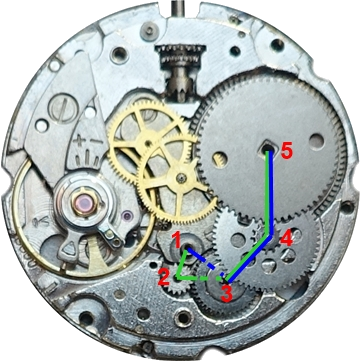

So let’s take a closer look at the Citizen 6000’s automatic. First, the rotor must be removed.

The rotor has ball bearings, and on the back you can see the wheel rim that engages with the reduction wheel at the top of the picture at 6 o’clock.

In this movement, the automatic is not a module that can be removed separately from the rest of the movement, as is the case with the ETA 2824-2, for example. Here it is integrated directly into the movement. So we have to remove the above-mentioned reduction wheel and the ratchet wheel – the large wheel at about 3 o’clock – to be able to remove the combined train-wheel-bridge and barrel-bridge.

This is what it looks like underneath:

In addition to the wheel rim on the rotor, the automatic mechanism has four wheels (in the picture between about 4 and 6 o’clock) that ultimately turn the ratchet wheel and thus wind the mainspring. In the next picture, the ratchet wheel has been placed on top of the mainspring barrel to illustrate the power flow. Of course, this is normally above the removed bridge!

- Reduction Wheel

- Wig-wag pinion

- Satellite wheel changer

- Winding-up wheel

- Ratchet wheel

The green line shows the force flow for the case when the rotor rotates counterclockwise, the blue line correspondingly shows the force flow when the rotor rotates clockwise. The dashed lines show the power flow inside the satellite wheel changer (part #3). More on the power flow a little further down!

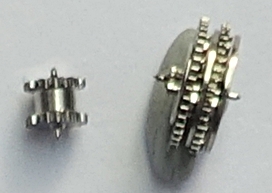

This is what parts #2 and #3 look like in side view:

The wig-wag pinion thus has a pinion at the top and bottom, while the satellite wheel changer is made up of several levels. The latter is, so to speak, the heart of the automatic, as it ensures that the winding-up wheel always turns in the same direction, regardless of whether the rotor turns clockwise or counterclockwise. It is therefore responsible for winding the movement on both sides.

Unfortunately, the satellite wheel changer cannot be opened without destroying it. Here I have sacrificed a specimen from another movement:

From the shape of the inner wheel, one can easily guess that the two small satellite wheels block it in one direction of rotation and not in the other. The satellite wheel changer is made up of two levels of this wheel combination. Each level thus functions like a pawl winding wheel, which is familiar from other automatic movements. The ETA 2824-2, for example, has two pawl winding wheels.

Incidentally, the satellite wheel changer also serves to decouple manual winding from automatic winding. With manual winding, the ratchet wheel turns, so that the wheels belonging to the automatic also turn. Without decoupling, the rotor would always rotate with the manual winding.

Let’s take another look at how the wheels of the automatic turn depending on the direction of rotation of the rotor:

In this video you can see that the ratchet wheel always turns to the right, regardless of the direction of rotation of the reduction wheel, thus tensioning the tension spring:

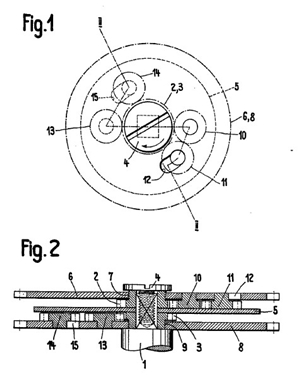

And who invented it? Exactly, the Swiss! In this case Omega, the well know watch manufacturer. Swiss patent CH308940 from 1955 describes the details of the satellite wheel changer, but there it is used to wind the watch manually or via an automatic that is only winding in one direction of rotation. CH308939, also from 1955, describes the application to a bidirectional winding mechanism. The next picture shows a section of CH308940.

Hi I’m trying to source a crown and winding stem for the 6001 Challenge diver version (62-6198). Any ideas would be great as Ive only just over 360 deg turn to lock the crown, even though the tube threads are visibly all there and look good.

Look for the following Citizen spare parts:

crown: 506-5061

stem: 065-107

Where can I find a Mainspring for this Citizen 6000 Automatic at? Thanks

Look for the Citizen spare part number 002-65. Should be easy to find.

Excellent post, I’m new in the watchmaker world, thank you for sharing your knowledge,