On a mechanical movement, a jumping second, also called dead-beat second, is something special, a so-called complication! By the way, in French it is called Seconde Morte, i.e. dead second. Of course, it’s only ‘dead’ between two jumps of the second hand!

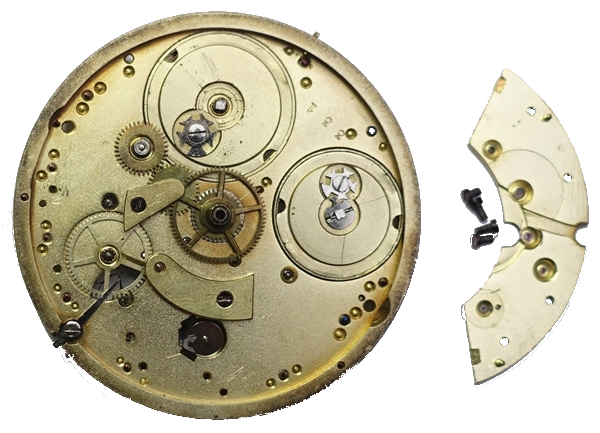

I present to you a pocket movement with dead-beat seconds that is about 140 years old. It has a diameter of 43 mm, and was probably once in a gold case, which was melted down. It already has got a then modern Swiss lever escapement with bimetallic screw balance, but still has got an old key winding system. Unfortunately, I could not find out the manufacturer of this movement.

The two mainspring barrels are immediately noticeable. The larger one serves the normal gear train for displaying the hours and minutes, the smaller one is responsible for the jumping seconds. On the dial side, you can see, that both mainspring barrels have or had Maltese cross stopwork. This serves to limit the winding and unwinding of the mainspring, so that only the optimal middle part of the torque of the spring is used.

Unfortunately, the Maltese cross stopwork was often removed from old movements. On the one hand, because after replacing a spring with a more modern one, its torque was much more linear. On the other hand, because a larger power reserve could be achieved. And sometimes, perhaps, because a hobbyist could not cope with the necessary pretensioning of the spring.

The implementation of a dead-beat seconds, which is presented here in a moment, was invented as early as 1776 by the Swiss Jean-Moïse Pouzait (1743-1793). In 1786, he developed his own lever escapement, the so-called Pouzait escapement. In 1788, he finally became director of the first watchmaking school in Geneva.

First, let’s look at the bridge side and see how the power flow is in the movement:

The power flow in the normal wheel train of the movement, from the mainspring barrel to the balance, is shown in green. Blue is the power flow of the wheels for the jumping second, which is located in the center of the movement. Marked in red is the escape wheel, which together with the pallet fork forms the escapement of the gear train. And that’s exactly where the escapement of the jumping second starts. Without it, the central second hand would turn in circles very fast, due to the tension of the spring in the smaller mainspring barrel. The escapement of the jumping seconds must therefore ensure that the second hand can only jump every full second.

So how does the jumping seconds escapement work? The secret lies under a bridge on the dial side.

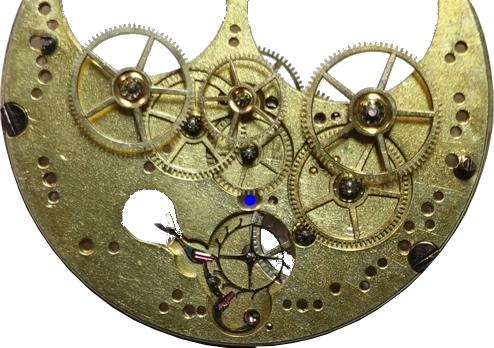

These are the parts here that interest us:

In the blue circle, you see the pinion of the escape wheel. It meshes with the fourth wheel of the normal gear train, which in this case doesn’t have a second hand! In the blue oval, there’s a small flirt, which looks a bit like a whip. This is how it looks from the side:

It can rotate in a circle to the right until it gets caught on the escape wheel pinion. After exactly one second, the escape wheel drive has rotated by one tooth and releases the small flirt again. The flirt turns 360° in a circle again and releases the wheels, which ensure that the second hand jumps exactly one second further. The following picture shows this again schematically:

Here you can see the small flirt as it rests against the escape wheel pinion, so the jumping second is stopped at this moment!

The pinion on the small flirt engages the gear train of the jumping second at the point marked in blue in the next picture:

Why does the escape wheel actually rotate exactly so that the small flirt is released exactly every second?

The balance of the movement has 18,000 bph (beats per hour), which corresponds to 5 beats per second. Each beat advances the escape wheel by half a tooth. The escape wheel therefore rotates by 2.5 teeth per second. The escape wheel has 15 teeth, its pinion, in which the small flirt engages, has 6 teeth. The rotation of 2.5 teeth of the escape wheel thus corresponds to the rotation of one tooth of its pinion (15 / 2.5 = 6). Consequently, the escape wheel’s pinion advances by one tooth exactly every second.

The part marked in green in the picture above is used to stop the jumping second by a lever on the side of the movement, if necessary. The small flirt then simply remains attached to this part. In the schematic view, this corresponds to the dotted line. The normal gear train for displaying the hours and minutes can work without jumping seconds. On the other hand, the jumping second also needs a running gear train, since both escapements mesh with the escape wheel.

Finally, a picture showing the disassembled movement. Quite a few parts…

By the way, the small flirt took me about two hours to assemble it in the movement after cleaning. Its weight distribution is so unfavorable that it is hardly possible to put it into one of its bearings on one side and to put on the bridge or the cock on the other side. Next time, I would leave the bridge of the jumping seconds gear train and the cock of the flirt on the dial side undismantled.

Even today, the jumping second is not completely extinct. It can be found, for example, in the Richard Lange Jumping Second model from A. Lange & Söhne:

There is also a very nice animation by A. Lange:

If you are lucky, you can also find a vintage watch with the famous Chézard 115/116/117 or 7400/7401/7402 as movement, which also has jumping seconds.