Today I’m going skating on black ice! Why? Every watchmaker and watch hobbyist has their own philosophy when it comes to oiling movements. Ask three watchmakers and you’ll get five different answers. And many movement manufacturers, in turn, have their own ideas and sometimes regulations.

So this is not a scientific treatise on how to oil movements, but a practice that has proven successful for me personally.

In order not to make things too complicated, I will limit myself in the following to movements with the following characteristics:

- Watch movements

That is, movements of wristwatches and pocket watches. Anything larger is called a clock movement. - Swiss lever escapement

No cylinder escapements, pin lever escapements, co-axial escapements, quartz movements, etc. - Beat rate up to 28,800 bph

Many older movements, especially in pocket watches, have a beat rate of 18,000 bph, newer ones usually 28,800 bph. Movements with higher beat rates are rare, but have specific oiling requirements. - Movements from manufacturers who believe that only they themselves or watchmakers qualified by them for a lot of money can oil the movement are excluded here.

Important:

Before oiling a movement, it must be cleaned. Re-oiling without prior cleaning will cause the old dirt, together with the oil, to form a great emery compound that will ruin the bushings.

The necessary tools

In order to oil a movement, we definitely need the right tools to put the oil in the right places, so-called oilers. In addition, vessels in which small amounts of the respective oil are taken with the oiler, the oil cups.

When oiling a movement, the oil should never be taken directly with the oilers from the supplied bottles in order to avoid contamination. There are also automatic oilers in which the oiler and oil cup are integrated, so to speak. We will deal here only with the classic manual oiler.

For oilers, there are assortments whose tips range from very fine to very wide. For small movements, two variants are usually sufficient, one very fine and one medium. These often have the colors black (very fine) or blue (medium), but this depends on the manufacturer.

For the oil cups a low-priced model is good enough. For the oilers I recommend the simple models of Bergeon, since their tips are more precisely manufactured than those of most oilers of cheap suppliers. Especially with automatic oilers, if you buy cheap, you buy twice!

Traditionally, you use elderberry slices to strip excess oil from oilers. I use Rodico for this. This is also ideal for dabbing off too much oil or oil that has landed in the wrong place on the movement. I prefer the green Rodico version for this, but the gray premium version also serves its purpose.

Oils and greases – the basic equipment

Here we will first deal with the basic equipment of oils and greases. We will see later that there are of course many more possibilities and variants.

So what do we need to get started?

- An oil for the bushings of the high-speed wheels, i.e. for the escape wheel and the fourth wheel. For movements with central second or central chronograph second, also for the axles of these wheels. In addition, for the bushings of the balance wheel.

My recommendation:

Moebius 9010

- An oil or grease for the pallet jewels.

My recommendation:

Moebius 9415

Up to a beat rate of 21,600 bph, the Moebius 9010 is also sufficient, above that, something more viscous in the direction of grease is needed. If you only disassemble vintage movements, you can do without Moebius 9415.

- An oil for most other bushings, including the third wheel, the center wheel, the mainspring barrel and the minute wheel. Also for the parts of the winding and hand setting mechanism.

My recommendation:

Moebius D-5 (relatively cheap), Moebius Synth-HP 1300 (more expensive), Dr. Tillwich Sorte 1 – 3 (cheaper than D-5).

- A grease for parts on which pressure is applied, such as the hammer and the pillar wheel on chronographs.

My recommendation:

Dr. Tillwich B52

For simple movements without complications, you can get along with two oils, the Moebius D-5 and the Moebius 9010!

Manufacturer’s oil recommendations

Some manufacturers provide technical documents for their movements, which also contain detailed oil plans. You do not have to follow these slavishly, but you should at least orient yourself to them!

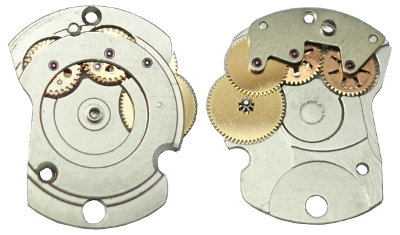

The two following pictures show excerpts from the Sellita SW200-1 documentation. In addition to the oil types, the points to be oiled are also indicated as well as an indication of the amount of oil to be applied.

And here is an excerpt from the oil plan of an ETA 6497-1:

It’s worth looking at some oil plans from different manufacturers to get an overview!

General tips for oiling

* Teeth and pinions of the wheels, only their bushings are oiled

* Bushings of the pallet fork, as the axis only moves back and forth

* Impulse jewel of balance

* For chronographs, the driving wheel, the bushing of the sliding gear, the bushing of the minute recorder and the minute recording jumper

- Less is more when oiling

The rule “a lot helps a lot” does NOT apply to watch movements! Too much oil is more harmful than too little. If the oil sink is filled too much, it will overflow and the oil will attack the plates. If the oil is filled correctly or even a little too little, the capillary force keeps the oil in the bushing and in the bushing sinks.

- First assemble, then oil

In most cases, the movement will be assembled first and then oiled. Exceptions are the balance (see below) and the bushings, which may be covered by other movement parts after assembly. This happens occasionally with the minute wheel, which covers the bushing of the third wheel, for example. And of course with automatic modules, which are mounted on the base movement.

- Normal bushings with oil sinks

These are almost always found in the gear train from the escape wheel to the center wheel. The oil sinks should be about half full after oiling.

- Pallet jewels

Before oiling, the mainspring should be wound up a little.

Only the exit pallet is oiled. To do this, apply a small amount of oil to the surface of the pallet that is in contact with the escape wheel. Then move the pallet back and forth a few times so that the pallet makes contact with some of the teeth of the escape wheel one after the other. Repeat this process 4 to 5 times until all the teeth of the escape wheel are wetted with oil.

The entry pallet receives the oil via the teeth of the escape wheel. The entry and exit pallets can be distinguished as follows:In the case of the exit pallet, the bevel increases from the inside to the outside, while in the case of the entry pallet it is the other way round:

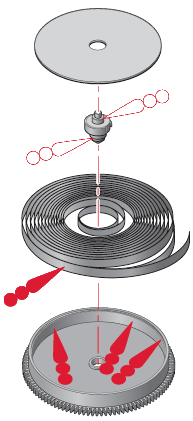

- Balance

The bushings of the balance should be oiled from below, i.e. not on the side of the cap jewels, even if you could remove them on balances with shock protection in order to oil from above. When oiling from below, however, care must be taken to ensure that the needle of the oiler is so thin that you can push the oil through the pierced jewel to the cap jewel.

The correct way to oil the balance would be to separate the balance cock from the balance on the hairspring stud. But then you have to bring the two parts together again. With a little practice, it is also possible to oil through the balance spring without lubricating it with oil. To do this, place the balance cock upside down on the table, lift the balance slightly with tweezers and find a suitable angle through the hairspring with the oiler in your other hand. If necessary, the balance cock must be weighted a little so that it is not pulled upwards with the hairspring.

The professionals here take an automatic oiler for oiling, as with this there is no risk of polluting the spiral.

This is how the result should look then, i.e. the diameter of the oil drop should not exceed 2/3 of the diameter of the cap jewel:

- Pawl winding wheel

Most manufacturers today recommend not cleaning and re-oiling automatic pawl winding wheels, but replacing them with new ones.

If you still want to oil them, either apply a tiny amount of Moebius 9010 to the pawls or dip the pawl winding wheel in Lubeta V105 (immersion lubrication) and blow away the residue with compressed air.

Lubeta V105 is a mixture of medical gasoline and Moebius 9010 in a 100:3 ratio, so if you want, you can make it yourself.

- Automatic module and rotor axis

The bushings of the wheels of the automatic module and the rotor axis can usually be oiled with Moebius D-5. If the rotor has ball bearings, oil the ball bearings with a very small amount of Moebius 9010.

- Center wheel with slipping clutch, hour wheel

In many movements, the slipping clutch, which allows the hands to be set, is located on the canon pinion, which is pressed onto the center wheel.

The axis of the center wheel is provided with some grease, e.g. Dr. Tillwich B52, before the canon pinion is pressed on. The axis of the canon pinion is then given a very small amount of Moebius D-5 before the hour wheel is laid on.

- Mainspring and barrel

Reasonably modern Nivaflex mainsprings are self-lubricating, so they do not need to be greased or oiled. Nivaflex mainsprings have been around for more than 50 years and can be recognized by their silver color.

Older mainsprings often have a brownish or bluish color. These are provided with a thin layer of grease, preferably by pulling them through a lightly greased cloth. There are also special tweezers that have grease on the inside so that the spring can then be pulled through. Too much grease can cause the coils of the mainspring to stick together.

You can apply a thin layer of grease or Moebius D-5 to the base and cover of the barrel. Here, however, opinions differ as to whether this makes sense. I tend to do it, because there are often scratch marks in these places on older movements.

A special requirement applies to the mainsprings of automatic movements. Here, the inner wall of the mainspring barrel is greased with a little Moebius 8217, Klüber P125 or Dr. Tillwich B52, since the mainspring slides along the inner wall when fully wound and is not fixed to the wall as in manually wound movements. Alternatively, or in addition, the outermost coil of the mainspring can also be provided with a little of the above-mentioned greases.

Finally, don’t forget to apply D-5 to the barrel arbor at the points where it touches the barrel.

- Epilamization

Epilamization is a process for the surface treatment of parts which prevents the spreading or running of oils on the part’s surface and the resulting loss of lubricant. The aim is therefore to keep the oil where it belongs. Epilamization is applied to the surface that the oil is not supposed to wet. If the oil is surrounded by epilamized surfaces, it cannot spread there, so it always creeps onto the untreated surface.

This treatment is often used on the escape wheel, the pallets and the balance staff. The components are first dipped in an Epilame solution, such as Moebius Fixodrop ES/BS-10 or Dr. Tillwich Antispread E2/200 FE 60.

Then run the movement unoiled, i.e. dry, to rub off the epilame on the contact surfaces. This is exactly where the oil will be applied later. Some manufacturers now even recommend epilaming all plates and bridges.

Unfortunately, the Epilame solution is quite expensive and evaporates faster than you can watch!

Andreas Kelz,

Thank you so much, It is a significant topic for any beginner and so professionally laid out in layman’s form,

Edmund…….Alberta,