The history of Ultra goes back to 1911, when the watch company Geismar & Cie from Besançon registered the Ultra brand. After the company went bankrupt, it was taken over by Paul Maillardet & Fils in 1937.

The aim was to build up a watch manufactory that also produced movements. The Compagnie Industrielle Horlogère was founded for this purpose. In order to give the Ultra brand its own identity as a manufacture, Ultra SARL was then founded in 1946 with its headquarters in Morteau, France. However, production was located in the old Tarragnoz mill in Besançon.

The pocket watch movements

Let’s now take a look at Ultra’s movements, first the pocket watch movements.

The first movement, the Ultra 364, is listed in a 1933 Geismar catalogue. The diameter given there is 16´´´ (French lines), but measured it is more like 16 1/2´´´.

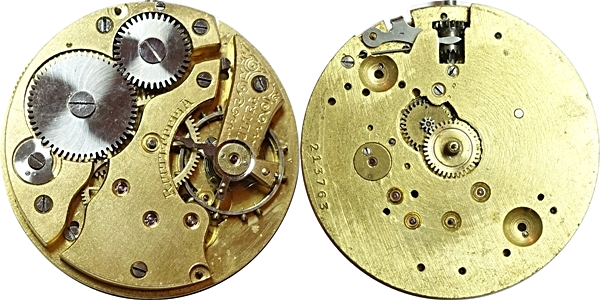

Ultra 364:

The 364 has a swiss lever escapement, a small second, a monometallic screw balance with flat hairspring, crown winding with pin setting, 15 jewels, no shock protection and oscillates at 18,000 bph (beats per hour).

This movement was also used in watches of the brand Chronomètre Triomphe. Unfortunately, I couldn’t find out whether this was an Ultra brand, or if they just bought Ultra movements.

The second movement, also listed in the 1933 catalogue, has only the calibre designation 18´´´, although it actually has a diameter of 18 3/4´´´:

Ultra 18´´´:

The visual similarities to the Ultra 364 cannot be overlooked and the technical key data are also largely identical:

Small second, monometallic screw balance with flat hairspring, crown winding with pin setting, 15 jewels, no shock protection, 18,000 bph.

A characteristic feature is the curved regulator arm, the indication of which is not on the balance cock as usual, but on the gear train bridge:

The balance cock is hallmarked ULTRA, on the Ultra 364 shown above this can be found on the dial side.

Presumably, both movements were developed and built into pocket watches before 1933, since crown winding with pin setting was no longer fashionable at that time.

The third pocket watch movement, the Ultra 41, is illustrated in the 1946 Cétéhor catalogue. At 18 1/2´´´ in diameter, it is minimally smaller than the second movement, but has much more modern bridge shapes.

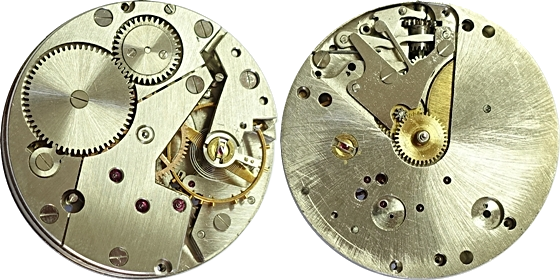

Ultra 41:

Like the movement shown above, it has a monometallic screw balance, 15 jewels and no shock protection. Here, however, a Breguet hairspring was used instead of a flat hairspring. The movement also has the more modern crown winding system without pin. This movement also oscillates at 18,000 bph.

The corresponding pocket watch looks like this, but the glass and the glass rim are missing:

The Ultra 41 was probably built until the end of the 1950s. Here is a certificate of accuracy from the end of 1951:

The Ultra 41 was further developed by Ultra in several stages:

Ultra 410:

The movement is hallmarked Ultra 410 under the balance, is red gold-plated and has an Incabloc shock protection. Instead of the Breguet hairspring, a flat hairspring was used here again.

Ultra 420:

Besides the silver colour, the Ultra 420 seems to differ from the 410 by a different shape of the balance cock as well as a different shock protection. Here, an Antichoc 102 is fitted instead of the Incabloc.

Ultra 421:

Technically, I could not find any differences to the Ultra 420. The optical differences are also rather marginal:

- Polished setting lever spring

- Hole on the dial side around the escape wheel jewel. Presumably for attaching a cap jewel. In fact, the 421 also seems to exist with 17 jewels. In addition to the mentioned cap jewel, the minute wheel is then presumably jewelled on the bridge side.

- Ultra logo under the balance wheel (compare with the pictures at the very top and very bottom of this article!):

The wristwatch movements

Of course, Ultra also made wristwatch movements. The oldest seems to be a hand-wound movement with a diameter of 10 1/2´´´ listed in the above-mentioned 1933 Geismar catalogue, which unfortunately has no more precise calibre designation. The movement is also shown in the Cétéhor catalogue of 1946 and in the Flume catalogue K1 of 1947.

The movement has a modern swiss lever escapement, manual winding, a monometallic screw balance, 15 jewels, a small second, but no shock protection.

Ultra 10 1/2´´´:

The Ultra 10 1/2´´´ shown is fitted in this watch:

The Ultra 10 1/2´´´ is also available with indirect sweeping second as Ultra 10 1/2´´´ SC:

The second wristwatch movement, the Ultra 602, was developed around 1950 (1947?). It also has 10 1/2´´´, manual winding, a monometallic screw balance, 15 jewels and a small second. The very early models have no shock protection, the later ones have an Incabloc.

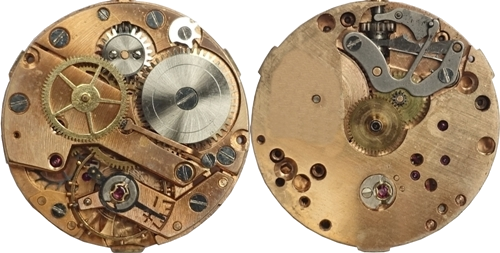

Ultra 602:

The movements are often labelled ULTRA 602 under the balance. Unusual in this movement are the three bearing surfaces on the dial side that protrude beyond the edge of the movement.

The next picture shows the watch belonging to the 602 shown above:

Due to the dedication of the Saarbergwerke (Saar Mines) on the bottom cover, it can be dated to 1955. Gold-plated and with a diameter of 34.5 mm, the watch is a typical representative of its time! The bottom cover, which is screwed on with an extra ring, is untypical. Some of you may be familiar with this from Russian diving watches.

There is also a version of the Ultra 602 with a date, the Ultra 606:

I could only identify it by the inscription Ultra 606 calendrier on the dial, as it is not listed in any movement finder I know of.

The date mechanism is very simply constructed. A finger on the hour wheel drives a star-shaped date wheel every twelve hours. This has alternating short and long prongs. The finger advances both versions of the prongs, but only the long prongs advance the date wheel every 24 hours.

The second movement of the Ultra with (indirect) sweeping second hand was the Ultra 702.

Although these movements are marked 602 under the balance, they are immediately recognisable by the indirect second.

Before we get to the highlight of Ultra’s movement development, let’s take a look at the Ultra 904. The oldest reference I could find to this movement is from the Flume K1 catalogue in the 1957 part.

Ultra 904:

It has a diameter of 10 1/2´´´, 17 jewels and a direct sweeping second. The Ultra 904 has some visual similarities to the French Parrenin 90, but is not identical to it.

The Ultra 904 is also available with date (seen in an Ultra Prestige Calendrier).

The Ultra Superautomatic

Now let’s move on to the highlight of Ultra’s movements, namely the Ultra 603 and Ultra 703 automatic movements. Ultra actually developed the first French automatic movement around 1950! It consisted of a module that could be mounted on the base movements 602 or 702.

The automatic movements from Ultra were built into the so-called Superautomatic. These are quite rare today and the movements are often in poor condition.

Unfortunately, my specimen of an Ultra 603 is missing the rotor of the automatic:

A kind watch enthusiast sent me a picture of his movement with rotor:

The winding mechanism, which works in both directions of rotation, is based on the same principle as the well-known Magic Lever winding mechanism by Seiko, a variant of the IWC Pellaton winding mechanism. However, Seiko’s Magic Lever only came onto the market in 1959!

An eccentric driven by the rotor (in the centre of the picture) moves a carriage whose two spring-loaded pawls drive the winding wheel at the top of the picture (one pawl or the other, depending on the direction of rotation).

The pinion on the winding wheel in turn engages with the ratchet wheel of the base movement and thus winds the spring. For this purpose, the ratchet wheel is built much higher than in the normal 602. Unfortunately, Ultra did not use an automatic spring with a sliding bridle in the design and instead installed a slipping clutch made of copper plates between the ratchet wheel and the barrel arbor (shown in the picture below) to prevent the spring from being overloaded. Unfortunately, this clutch tends to slip too soon after a short time. Then not enough power reserve can be built up by the rotor movement.

As early as 1958, Ultra licensed the automatic module to the Japanese manufacturer Citizen, who used it to equip its first automatic movement, the Citizen 3KA.

Addendum:

A few weeks after this post appeared, I was able to get hold of another copy of the Superautomatic, which fortunately still works:

On this specimen, the dial simply says Automatic instead of Superautomatic. And the inscription on the rotor claims that the movement has 17 jewels. In fact, it has 19 jewels, just like the movement shown above. I wonder what the reason for this understatement was.

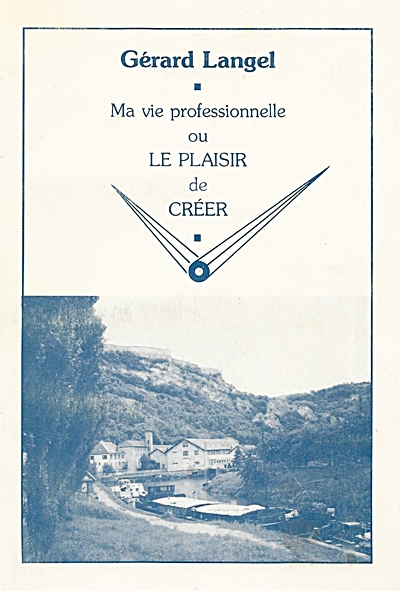

Gérard Langel

The mastermind behind the development of the automatic module was Gérard Langel, who is listed as the inventor in the corresponding patents:

- FR62801 (France) from 1950

- CH290359 (Switzerland) from 1951

- DE875629 (Germany) from 1951

- GB703362 (UK) from 1951

- US2696073 (USA) from 1951

For a long time I could find out almost nothing about Gérard Langel until I happened to discover this antiquarian book in which he left us his biography in 1985 (“My professional life or the pleasure of creating”):

Langel was born 21.02.1911 in Courtelary, Switzerland. Having previously worked at LIP, he joined Ultra in 1945 and even became a partner in the company in 1947.

Initially, however, Langel and his colleagues were busy rebuilding watch and movement production after the war, especially with the difficult procurement of the necessary machinery. During this transitional period, according to Langel, calibres from the manufacturers Jeambrun (9 3/4´´´) and Cupillard (10 1/2´´´) were initially built into the watches.

Unfortunately, very little information about the development of the automatic module can be found in his biography. The idea of the module came to him because a new development of a whole movement would have been too expensive. Langel says that Ultra developed a movement with the calibre designation 233 with 10 1/2´´´, which was available with small second and with indirect sweeping second. This movement was delivered from 1947 onwards. This calibre 233 was again the basic movement for the automatic module. Was 233 the working name for the later calibres 602 or 702?

At first, I thought it was a mistake in the biography, since there was also a calibre 233 with 10 1/2´´´ from Cupillard and Ultra used Cupillard movements.Until I found a hint of a relationship between the calibres 233 and 602 in the form of this spare part envelope with balance shafts:

Gérard Langel also began developing a form movement with the designation 15 x 24 (presumably millimetres) at Ultra. It was never produced, however, because Langel left Ultra after a change of co-owners and disputes with the new owners. In 1951, he founded his own company, CRYLA, to produce the 15 x 24 calibre. Unfortunately, I do not know what became of this plan. CRYLA still exists today, but has long since ceased to be owned by the Langel family.

Third-party movements

Later on, Ultra did not only use its own movements, but also movements from other manufacturers. In particular, all ladies’ watches have movements from other manufacturers, since Ultra did not build small movements. Ultra even gave some of the movements from other manufacturers their own calibre designations:

- Ultra 514 = FHF 75 (5 3/4 x 8 1/2´´´)

- Ultra 902 = Felsa 465 (11 1/2´´´)

Ultra and Citroën

What became of the Ultra company later?

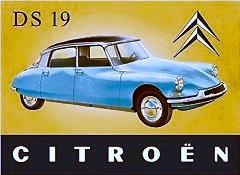

In the best times, the company is said to have had about 180 employees at the two locations (another source mentions 250). In 1963, Ultra succeeded in being selected as the supplier of the on-board clock for the futuristic Citroën DS 19 and ID 19 car models.

Later, in cooperation with the company E.D. Veglia, these clocks were also installed in other Citroën and Peugeot car models. Unfortunately, I could not find out anything about the inner workings of these clocks.

Decline and rebirth

Due to the poor economic development in the 1970s and disputes in the owning family, the company went bankrupt in 1969 and was finally dissolved in 1972.

A good forty years later, the brand was revived by an entrepreneur in 2015. The only address for the company that can be found an its website is in Hong Kong [Ultra (Asia logistics) Unit 3, 4/F, B1, Yau Tong Industrial City, 17 Ko Fai Road, Yau Tong, Hong Kong].

The company sells some models of the Ultra Superautomatic with a movement called Ultra 803. Of course, these movements have nothing to do with the old automatic modules anymore. They are Japanese Seiko Sii NH15 movements.

Would anyone have any information about an ULTRA silver colored pocket watch – watch face states ULTRA Precision (ie no number), Shockproof, 17 jewels.

Thank you in advance! Curious to understand likely place and timing of production and any other details.

You have to open the watch and have a look at the movement. If you find the movement in this article, the watch was made by Ultra in France. And the movement gives some indication about the production period. If it has a different movement it was most likely made by another company.

They also made some Dive Watches.

I got one that was given to me around 1980.

Ultra went bankrupt in 1969 and was finally dissolved in 1972. I know that there are watches from around 1980 using the Ultra brand , but they were probably made by someone else.

Interesting History, thanks.

I have a Superautomatic, sadly also without the rotor.

How do I remove the winder, in order to remove the mechanism from the case. The case has some damage, possibly from an accident, and I would like to straighten it, if I can’t replace it.

Any joy finding replacement rotors since writing this article?

Regards

There is a small hole in the automatic module close to the winding stem. A screw can be seen through this hole. Loosen this screw (just one or two turns) and you should be able to remove the winding stem.

Finding a replacement rotor will only be possible with a lot of luck.

This is such a nice article. Thank you very much for writing! There is very little information on the internet about Ultra. Your explanation of the different calibres is greatly appreciated!